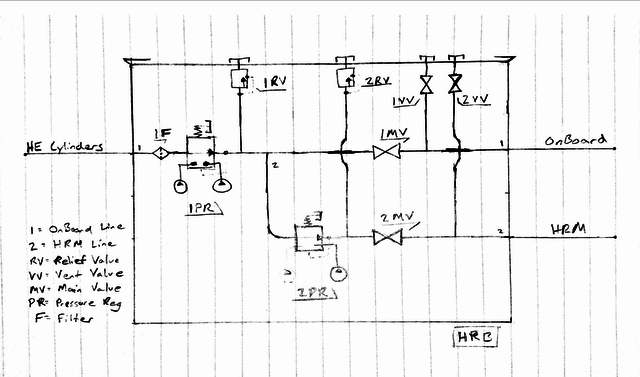

As Design Lead for The SDSU Rocket Project, I led the design, assembly, and operation of a new multi-use remote helium pressurization system to safely pressurize the Galactic Aztec Heavy rocket from 200 feet away.

System Operation General Description:

- A Helium K-Bottle is connected via a 10' 4000 psi perforated hose to the Helium Pressurization Bay (HPB) inlet.

- Before opening the k-bottle, all valves are ensured closed and all regulators unloaded.

- Opening the pressure source allows helium to flow into the system, through a 15 micron filter, and into the first regulator with an inlet pressure gauge to show the gauge pressure of the source.

- For Galactic Aztec Heavy, the high pressure (~3000 psi) helium is then regulated down to 2000 psi.

- This Helium flows to a tee. The main line leads to high flow ball valve and the secondary line leads to a low pressure regulator.

- A 200' high pressure line is then connected between the HPB and the rocket. Once the main valve is opened, Helium moves through the line and pressurizes the rocket.

- Once the rocket is pressurized and stable, the main valve is closed and a vent valve is opened to vent the main line. A check valve on the rocket would prevent the rocket from depressurizing.

- At this point in time, the rocket is fueled and pressurized making it unsafe to approach. The high pressure helium line must be disconnected remotely.

- The low pressure regulator allows the user to regulate the helium down to 150 psi. A valve is then opened to allow the low pressure helium to flow through an additional 200' line leading towards the rocket.

- This second line is connected to the Helium Release Mechanism (HRM), which uses two actuators to pull down on a high pressure quick disconnect.

- The HRM disconnects the main line from the rocket and the rocket is ready to launch.