I have a strong background in composites that originate from my participation in The SDSU Rocket Project’s Composites Section. My expertise in this area led to being hired as an intern at San Diego Composites (SDC) for the summer of 2016, where I worked with large tooling, mandrels, filament winders, pre-preg, and more. I have specifically manufactured or worked on:

- Composite Fairings

- Autoclaves (controls temperature and pressure providing consistent cure cycles)

- Ply cutter (used to cut various 2d plies from .dxf files for complex geometry)

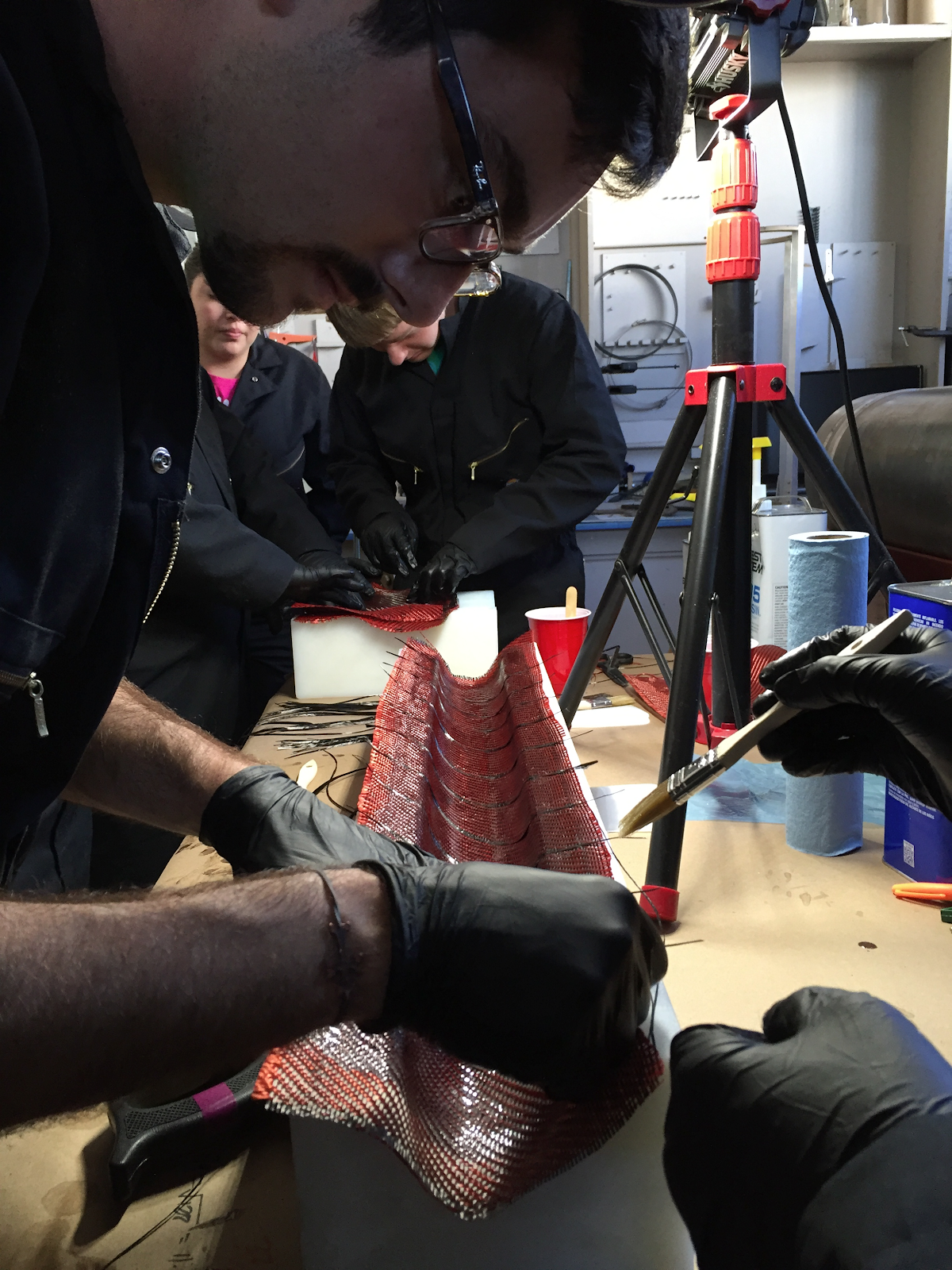

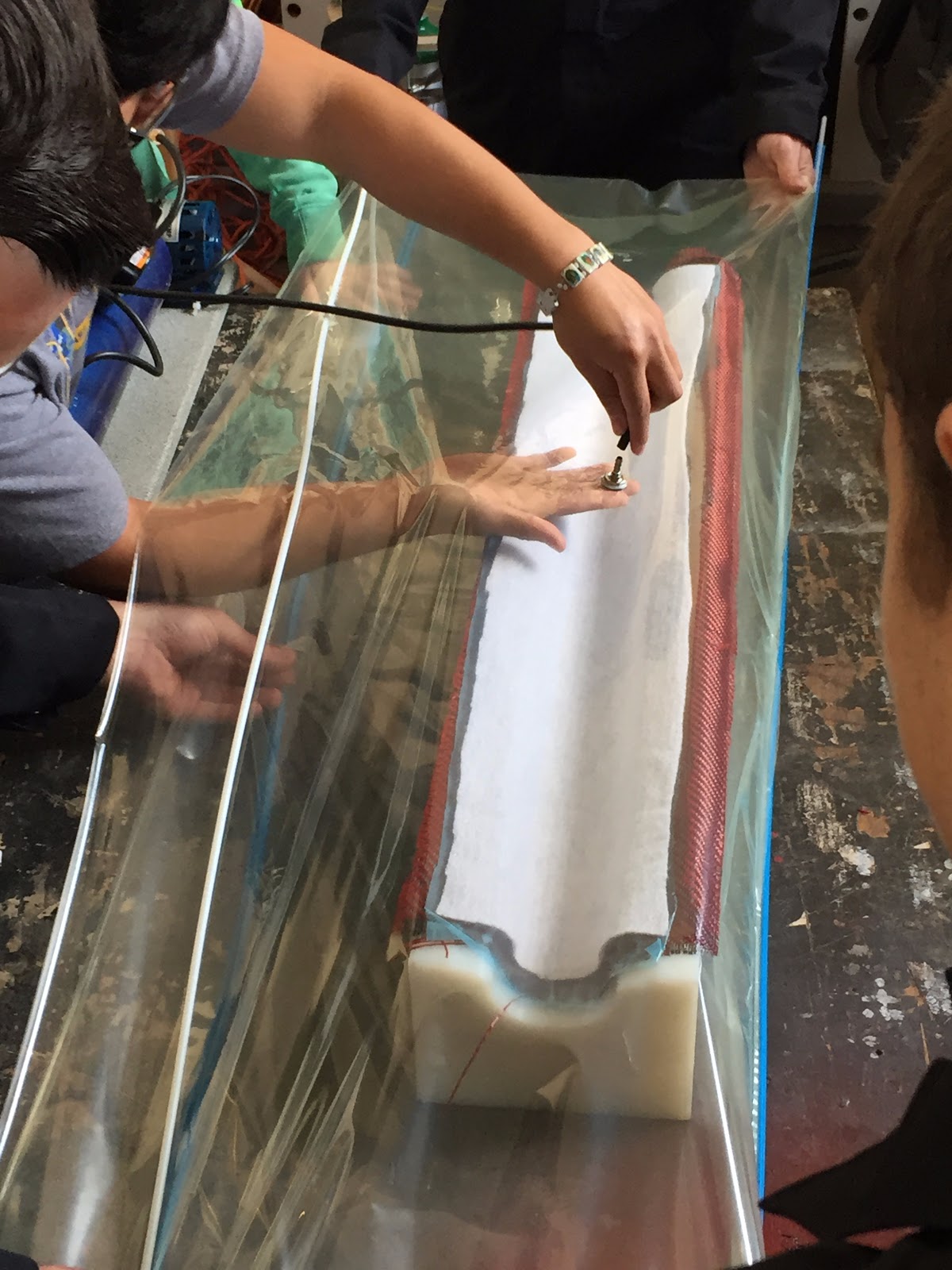

- Wet layups (liquid resin/hardener is applied wet in between the layers of material)

- Pre-preg (pre-impregnated composites allow accurate distribution of epoxy)

- Filament winders (SDC used to create large missile canisters using around mandrels)

- Honeycomb Core (lightweight internal structure for great compression properties)

My experience with composites strongly contributes to my overall skills as an Aerospace Engineer. All featured photos are from my SDSU Rocket Project experience.